-

What is the Manufacturing Execution System (MES)?

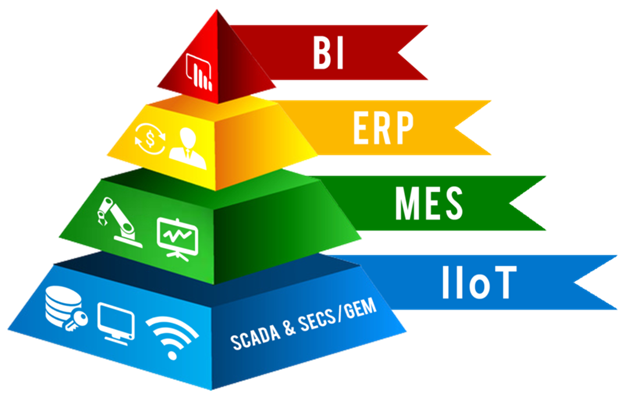

MES (Manufacturing Execution System) is an enabling technology for building smart factories.

MES is a system consisting of computers and software used in factories, used to track, monitor, and store information from input materials to output products. MES provides information that helps plant decision-makers understand the current state of the plant to optimize and improve production operations. The MES system works online in real-time to control multiple production equipment. (inputs, people, machines, and support services).

MES provides a comprehensive and in-depth view of all factory operations, helping to ensure efficient execution of operations and improve production output.

-

Benefits of the MES system

The production management and operating system (MES) bring production enterprises many practical benefits:

Production optimization: Through the use of the MES system, operational processes manage effectively, equipment is maintained proactively, product quality is assured, reducing downtime & manufacturing costs

Increased competitiveness: the MES system helps businesses adapt flexibly to market changes, improves competitiveness.

Be more proactive in decision making: information is updated continuously in real-time, providing a complete picture through visual reports to help managers make quick business decisions. -

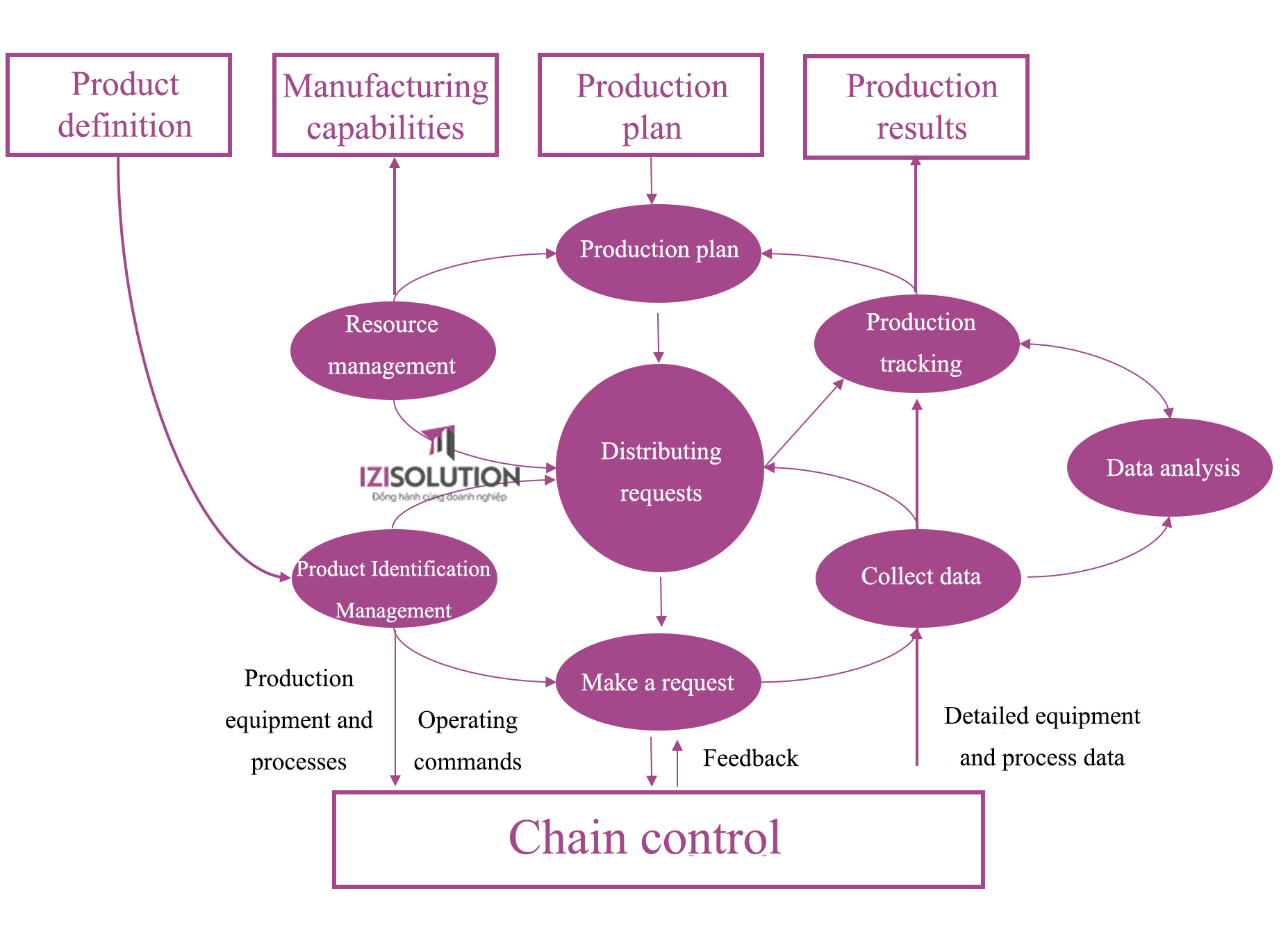

Functions of the MES system

The MES system includes the following main functions:

Management of product identification in the smart factory

Management of product identification in the smart factory Resource management in the smart factory

Resource management in the smart factory Production plan

Production plan Make a request

Make a request Production data collection

Production data collection Production tracking

Production tracking Data analysis

Data analysis -

Consulting & implementing MES

IZISolution is a leading unit in digital transformation consulting in Vietnam, which includes consulting & implementing MES production management and operating systems. With experienced experts and an enthusiastic implementation team, IZISolution will help businesses implement MES successfully. Implementation steps include:

Survey & Fit Gap Features

Survey & Fit Gap Features Prepare data

Prepare data Customization

Customization User training

User training Go-live system MES

Go-live system MES

Hotline: 096 4578 234 Support after go-live

Support after go-live